|

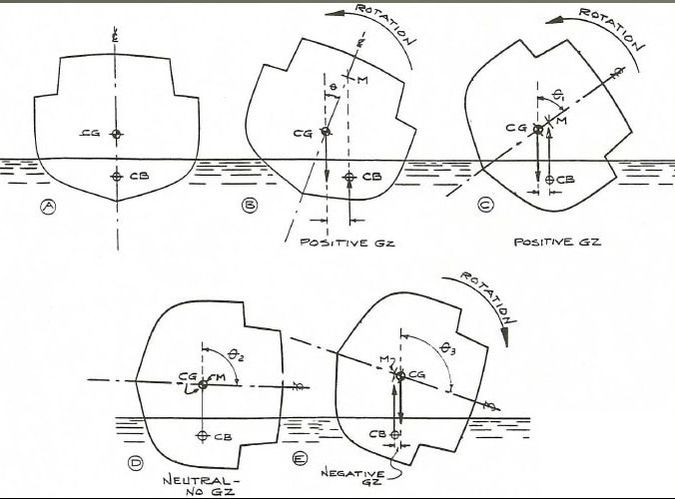

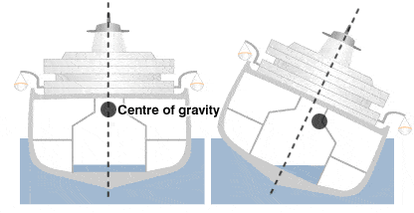

Recently, one of the owners on the Serenity suggested adding a hot-tub on the upper deck; I was glad when the rest of the membership voted it down for a variety of reasons (maintenance, upkeep, structural concerns, etc.), but one of the primary reasons for my opposing this proposal was that of stability. The stability of your vessel is something that recreational boaters very rarely take into consideration, but when you’re dealing with a larger vessel like our houseboat and a modification that will place thousands of pounds of water high up on that vessel, it’s something that must be factored in. In the commercial or government world any modifications to a vessel (even small vessels) would go through extensive engineering review and, if they were major enough to result in changes to the stability characteristics of the vessel, would require inclining the ship to determine the new stability values. Every ship is inclined when built to determine its stability characteristics, which essentially requires shifting large weights from one side of the ship to the other and measuring how far the ship heels over, which allows the determination of the metacentric height. The photo below of the NOAA Ship Delaware II is not exactly how an inclining experiment should go. The metacentric height (GM) is defined as the distance between the center of gravity (G) and the metacenter (M). The greater metacentric height, the greater the stability of the vessel. While you might think that just maximizing the metacentric height would be the best option, that results in what is referred to as a stiff ship and should be avoided. The term stiff ship refers to a ship that has excessive stability. The characteristics of a stiff ship would be a very short rolling period, which means the ship would return to upright after being heeled over very quickly and result in a very snappy and uncomfortable ride. The center of gravity is essentially the center of mass, and can be shifted by moving loads to different locations on the vessel (e.g. placing more weight lower in the hull will lower the center of gravity, and placing more weight up high will raise the center of gravity). The metacenter is a fixed point through which the buoyant force acts. Put another way, as the vessel heels over, the center of buoyancy shifts; if you drew a vertical line through the center of buoyancy at various states of heel, they would all intersect at the metacenter. The distance between the vertical line and the center of gravity is referred to as the righting arm (GZ) and results in a righting moment that pushes the vessel back to upright. As I stated above, having too much stability results in a very large righting moment and a “stiff ship.” Not only will this vessel be uncomfortable, but the quick, snappy righting can cause cargo to shift, throw loose gear/people about, and can cause structural damage. The opposite of a stiff ship is called a tender ship, which has a very small metacentric height and, as a result, a very small righting moment. A tender ship has a very long roll period, which means that the vessel will return to upright very slowly and has insufficient stability. A “tender ship” will resist rolling less, will roll more steeply, and will tend to remain heeled over for a longer period with a higher likelihood of capsizing. Neither a stiff nor a tender ship is desirable, but you want to be in a happy middle ground. Calculating the stability is not a trivial matter. Marine architects and engineers will have calculated values for the construction of any vessel, but these must be verified to complete the final modeling of the stability of the vessel and that is where the inclining experiment comes in. Once that test is done, the values are verified and placed in the ship’s stability book (now probably a computer program), which the master and chief engineer will consult every time they load the ship to determine the vessel’s stability prior to leaving port. Any major modifications, like adding a large mass up high, would have to be factored in and, if a permanent modification, would require a new inclining experiment to update the stability book. Recreational vessels generally won’t come with a stability book, but should be safe for all normal loading conditions within the limitations of their USCG capacity certification. However, if you start doing things well outside what might be considered normal loading, like adding a hot-tub, you better start thinking about stability. I doubt I could have tracked down any stability information for Serenity and, even if I could, I’d still want to do an inclining experiment. And this doesn’t even start to take into account the free surface effect of the water, which would further reduce the vessel’s stability. The free surface effect essentially refers to the tendency of a liquid in a partially filled tank to slosh to one side when the vessel rolls; that moving mass will increase the roll, which then increases the sloshing, which increases the roll in a positive feedback loop that can result in the loss of stability and capsizing of a vessel. As a result, most tanks on vessels have baffles that prevent fluids from freely communicating from one side of a large tank to the other and mitigate the free surface effect. This phenomenon has been the culprit for many vessel sinkings; particularly on ROROs (Roll-on/Roll-off cargo vessels), which have large open decks that allows water, once on board, to flow freely from one side to the other. The USCG investigation into the recent sinking of the El Faro, a RORO, determined that the free surface effect was the mechanism that ultimately sank the ship.

Needless to say, I was very pleased when our owners decided not to pursue putting a hot-tub on Serenity…besides, who would clean it? Until next time, here’s wishing you fair winds and following seas.

2 Comments

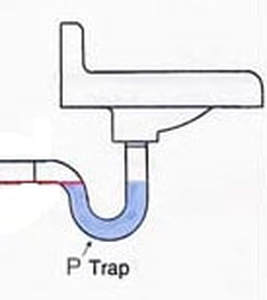

It’s that time of year again; the leaves are changing colors, the days are getting shorter, everything tastes like pumpkin spice, and, at least in my neck of the woods, the boating season has come to a close. That means it’s time to roll up my sleeves (then quickly realize that it’s too cold for short sleeves and roll them back down) and get to work on winterizing the Serenity for her long winter’s rest. I pushed for a winter lay-up period and, luckily, the other owners on Serenity have agreed that it makes sense to pull the boat off the water for the cold winter months. Our winter lay-up begins in November (as you’re reading this I am probably down in Bullfrog doing exactly what I’ve written here) with relaunching done in March. The chief reasons I wanted this dry-docking are: (1) If the boat is not in use, there is a drastically reduced chance of damage sitting in dry storage as opposed to being on the water, (2) it gives the boat a chance to dry out and hopefully prevent major maintenance issues due to mussel growth, (3) it results in a reduced insurance cost and can offset some of our costs for slip rental, which can be prorated, and (4) it allows for out of water repairs to be completed prior to the beginning of the next season, like replacing impellers and changing the lower unit lube oil. If there is the option, I would almost always opt to store my vessel on the hard over the months that it isn’t being used. Prior to being put up for the long winter’s nap, there are several things you need to do in order to make sure everything is in good shape when you pull the boat out of mothballs next Spring. I’ve winterized my fair share of boats over the years; the houseboat includes a few extra systems, but shouldn’t take more than a few hours to get ready for storage with a couple knowledgeable people (no word yet on how long it will take me and my dad). I like to winterize as much as possible while we’re in the slip, prior to haul out; pretty much everything except the main engines can be finished up prior to driving over to the ramp to be loaded up. General Maintenance Throughout the season, things have a tendency to break and the end of the year is always a good time to catch up on all the minor issues that have gotten overlooked. Fixing the loose door latch, replacing burnt out light bulbs, changing a broken light fixture, replacing the tank level sender units, rebuilding a leaking steering pump, replacing broken trim, and fixing a loose connection block on the marine head; I build a punch list over the months and then spend a couple days making sure everything is knocked off that list or, when missing all the required components, they are listed and planned for repair prior to relauch. I also include items like removing the canvas cover on the upper awning, making sure the deck chairs and tables are secured by tying them to the railings, giving everything a good cleaning, and generally making sure that everything is stowed to prevent anything from blowing away or wandering off. If you spend this time making sure everything is ship shape, it will make next Spring a whole lot easier. Fuel System Serenity carries about 400-galons of fuel and the last thing you want to have to deal with is that much stale gas. While there has been varying advice from different authoritative sources over the years, they have come to consensus and now advise storing your fuel tanks full, or at least at the 90% maximum safe fill level. With modern fuels you face several issues that weren’t present prior to the elimination of lead and the introduction of ethanol; most notably is ethanol’s propensity to absorb water and reduced resistance to microbial growth. Water is public enemy number one, and keeping the tank as full as possible reduces surface area of the tank and the volume of air that could allow for condensation. Long story short, it’s best to store your tanks full to prevent condensation and keep the gas dry. Adding a fuel stabilizer prior to the final fill up on all tanks is also advisable. A fuel stabilizer will add up to 24-months to the shelf life of your fuel. It reduces water absorption, increases lubricity, inhibits microbial growth, and boosts octane. I always try to add the stabilizer prior to the final fill up, so that the additive can be well mixed with the fuel, but realistically, the bumpy trailer ride to storage a few miles away will do a pretty good job of mixing it anyway. Potable Water Water is the greatest concern when winterizing in almost all the houseboat systems, so a logical place to start is the potable water system. Power of freezing water is impressive; just look at the cracks, potholes, and heaving in the roads throughout the Northeast to understand its immense destructive force. You want to get all the water off the boat and the potable water system is as good a place to start as any. Freezing water can burst pipes and rupture filter housings. Most of the damage I had to deal with in the plumbing system was caused by freezing. The Water Fixer filtration system had both filter housings burst, requiring replacement, and the stainless steel UV chamber had one end cap pushed off. Winterizing the water system begins with emptying the water tanks; you can simply use the pressure system pump to run water through the faucets until the tanks are dry, but I prefer to utilize a portable pump to drain the tanks by connecting to the drain spigot on the tanks and run the water overboard. The water heater tank is emptied in a similar manner. You do have the option of opening the drains and letting the tanks dump into the bilge, subsequently pumping the water out with the bilge pump, but I prefer to keep my bilges dry. Once the tanks are empty, you can focus on blowing out the water lines. The easiest approach I’ve found is to purchase a $5.00 blowout adapter, like the one pictured below. This fitting allows you to attach your air compressor’s chuck to the water inlet to pressurize the system. It’s then just a matter of opening the hot and cold at each of the faucets to allow the water to be blown out of the lines. It’s important to remember to open the valve to the water tanks to be sure to blow out those lines as well. You also need to open and empty the filter housings, and disconnect the line to the pump and allow it to drain out. The drain P-traps also need to be blown out, which I do with a wet/dry-vac, but could also be done easily by removing the P-trap and dumping them out. On Serenity, we have no gray water tank, and all the sinks and shower discharge directly overboard, so I don’t have to worry about any odors or sewer gasses. However, if your system does drain into a holding tank, it’s a good idea to refill the P-trap with RV-antifreeze. Black Water The black-water holding tanks need to be pumped out per our normal procedure, which includes back-flushing the tanks until the effluent is relatively clear and then priming the system with toilet chemicals and about 5-gallons of water. The seacocks for the toilets are then secured and I empty the filter housings. Then, leaving the filter housing loose, I run the pump to clear the lines of water, and try to blow the lines out with a wet/dry vac as best as I can. I will run the macerator pump to drain the blow and flushing lines, but usually that won't quite get all the water out of the bowl and I will have to suck it out with a wet/dry vac prior to filling the the bowl and macerator pump with RV antifreeze. Electrical Even your electrical system needs a little attention prior to winter. The only things I really do are to ensure that the water levels on the flooded lead acid batteries (inverter and starting batteries) is at the correct level and then make sure the batteries are isolated so that an errant load doesn’t drain them flat over the winter. You need to use distilled water and a bulb syringe to fill the batteries up to the maximum fill level, which is illustrated below for the Trojan inverter batteries that were originally on the boat. Many would advise pulling the batteries and storing them inside during those cold months. You might also put them on a trickle charger. I agree with this and take both of these steps on my small boats, but it’s not that simple with the houseboat. Serenity’s 12-batteries weigh a total of over 1100-lbs and would have to be hauled back to Colorado or Washington, since no heated indoor storage is available at the storage yard. For me that’s just not feasible, and I’ve never had any issues with the batteries just following the practice of isolating them to prevent discharge. Generator Now we’re getting to the nitty-gritty. The generator can easily be winterized while the houseboat is still in the water. Our Westerbeke has a closed cooling system with a heat exchange system that draws cooling water from the lake. The closed system is already filled with antifreeze, so you just have to worry about the raw water intake and wet exhaust. Now, the textbook method for winterizing the generator would be to pull the drain plugs in the exhaust manifold and on the heat exchanger, but I’ve found an easier approach. I close the seacock for the raw water intake, clean out and empty the sea strainer, and then disconnect the hose leading to the heat exchanger. I place the hose in a 5-gallon bucket filled with a few gallons of RV-antifreeze and then start the generator. It takes less than a minute of running to suck the bucket dry and start expelling the pink fluid over the side through the exhaust, thus displacing all of the water in the system with the biodegradable RV-antifreeze. When it looks like about 10-seconds worth of antifreeze left in the bucket, I have someone else start praying fogging oil into the carburetor, and then kill the generator. Then it’s just a matter of pulling the four spark plugs and fogging each of the cylinders, prior to replacing the plugs. Main Engines And finally, the main engines get their winterization only after moving over to the ramp for haul out. They will walk the houseboat onto the trailer and winch it into final position, so once you’re tied up at the dock by the ramp, you should be finished with the engines for the season. I like to get to the dock a little early so that we have time to do some of the winterizing prior to being hauled out. You can do this all after being hauled out, but if you want to run the engine on the hard, you will end up having to rent a run cart, if available, to ensure none of the cooling water ends up on the ground (even though under normal operation that water would be going right back into the lake…you’ll have to take that up with the EPA). Once we’re at the dock, I will shut off the fuel tanks and let the engines starve of fuel. Prior to them dying, I try to time it about right so that I can spray about 10-seconds of fogging oil into the carburetors on each of the engines; it’s easier if you do them one at a time. Once the engines have starved of fuel, you can fog each of the cylinders, but this can also be done after being hauled out. After the boat is blocked up, it’s time to finish up the winterization process. Aside from fogging the cylinders, that means draining the block and the exhaust manifold. I pull the plugs on both the manifold and the block and allow the water to drain into the bilge. I then remove the thermostat housing and use a wet/dry-vac to blowout the block and manifold. Once both drain holes are relatively dry, I shut down the wet/dry-vac and replace both plugs. I then pour RV-antifreeze into the thermostat housing port to fill the system. That would be the bare necessity for winterizing, but if there’s time I also like to replace the lower end lube oil and, while I’m at it, drop the lower end and replace the impellers. The impellers should last more than a year, but with the mussels in Lake Powell, I figure it’s better to be safe than sorry and open up the lower units to make sure everything is clear and put some new impellers in there. If an impeller should fail during the season, the only option is to haul the houseboat out again to work on it, which represents a $1000 obligation, so I figure the $30 for the impeller kits is well worth it.

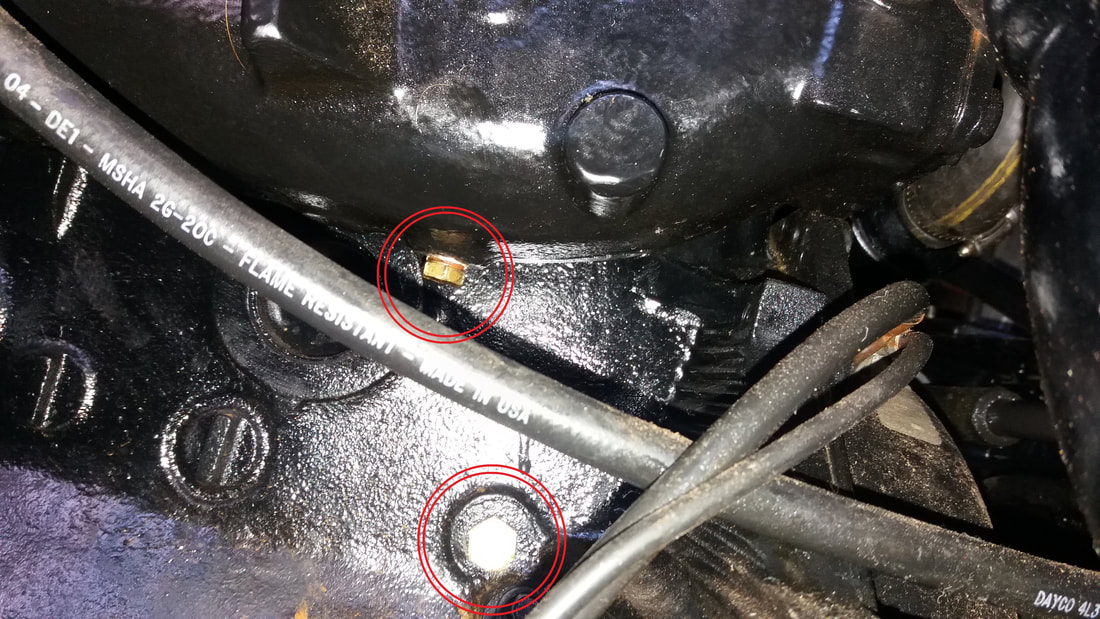

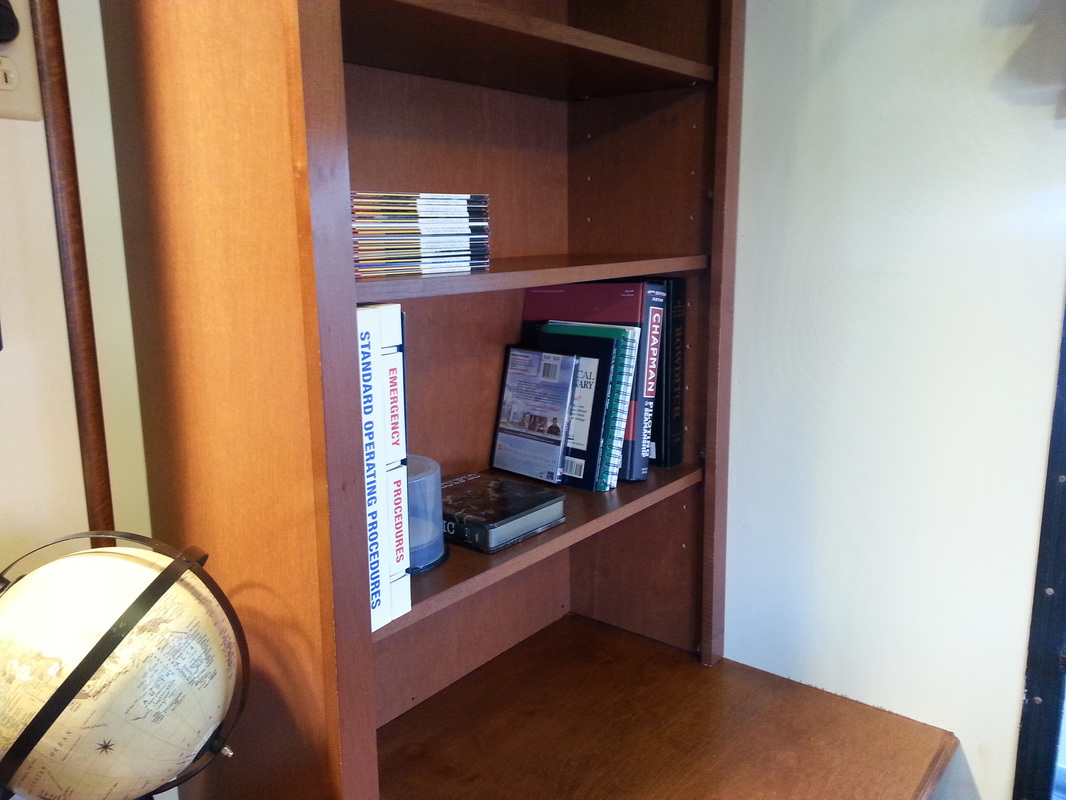

Even if you’re not dropping the lower unit, it’s good practice to replace the lower end lube oil prior to winter storage. If any water has made its way into the lower end, you don’t want it sitting in there all winter and potentially freezing. The Mercruisers have a reservoir for the lower end lube in the engine compartment, since there’s virtually no way for water to work its way up into those reservoirs, I don’t see a need to drain them and instead clamp off the hoses running down to the lower units. Then it’s just a matter of opening the drain and vent plugs on each of the lower units and allowing them to drain. I have been known to be a little impatient, and I will often use my compressor to blow the oil out from the upper vent hole in order to speed up the process. Once they’ve run dry, I’m free to drop the lower units and replace my impellers, but I won’t go into detail on that procedure in this post. Instead, assuming you aren’t replacing the impellers, you would just go ahead and refill the outdrives with lube oil, pumping it in from the bottom drain port until it comes out the upper vent port. Then you just have to remember to remove the clamps isolating the reserve reservoirs. With all this complete, it’s finally time to button everything up and head home. Until next time, here’s wishing you fair winds and following seas. At the zoo there was a monkey island surrounded by what was essentially a moat. The island had a lighthouse on it and in the moat along the shore of the island there was a concrete sculpture of a wrecked boat, broken in half. As early as three years old, I remember thinking about how cool it would be if I could somehow put it back together and have my own kid sized boat. I guess I’ve been dreaming of having my own boat for as long as I can remember; I always saw old broken down wrecks (be it a rotted out old wooden runabout or the rusted remains of an old shrimping boat on the Florida coast) as an opportunity to rebuild them to their former glory…I hadn’t yet learned how to calculate return on investment. I did just that with my deck boat in high school, but after I spent some time on the water I started to dream bigger; I wanted a yacht (a 58-ft Hatteras Long Range Cruiser, in case anyone wants to get me an early Christmas present), but I could never make buying such a large vessel make financial sense. It didn’t keep me from dreaming about rebuilding my perfect boat and all the features that I would want on it. Fast forward to early 2015 when I found myself the proud new owner of Serenity and I finally had my opportunity to build the perfect boat. Granted, some features you’d want on a transatlantic yacht don’t make as much sense on a houseboat on Lake Powell (Radar, Autopilot, EPIRBS, SSB radios, AIS, ECS, Gyro-compass, etc.), but plenty do and I had other features based on my houseboating experiences on Lake Powell that I wanted to incorporate as well. I’m going to highlight all the “bells and whistles” that I added to the boat that I think separate her from other houseboats. Flooring. What, floor coverings don’t sound like a feature you’d daydream about? I think that the right floor coverings are not only aesthetically pleasing, but also offer longevity and improved livability on the houseboat. As such, I took a lot of time making sure that I chose the right ones. I’ve already sung the praises of the Lonseal teak and holly flooring in my previous post on the interior, but I’ve got to bring it up again. This vinyl flooring that emulates a teak and holly sole ticks all the boxes for me; it looks good, it’s durable, and it doesn’t require maintenance. You can easily point out that material and installation costs exceed that of carpet, but given the fact that this should have a much greater life (hopefully never needing replaced) and isn’t going to get stained or trap the sand and dirt, I think the extra cost is justified. It is a commercial grade sheet vinyl, which is a waterproof barrier, has a long wear life, and is UV stable to prevent fading. The only thing you should ever have to do to keep this floor looking great is sweep and mop, which will be of great benefit in keeping the sand that will inevitably be tracked aboard in check. I did opt for carpet in the staterooms due to both the lower cost and the installation difficulties with the stairs. I like the feel of carpet in a bedroom, and, while I prefer hardwoods or tile throughout a house, I usually go with carpet in bedrooms as well. In order to get the best life out of the carpet, I purchased a short pile Stainmaster carpet that I hope will hold up for many years. On the exterior decks I went with a marine carpeting, but decided on a darker tan color instead of the traditional dark gray that you see on most boats. The reason for the dark tan was twofold, I figured it would be cooler on the feet and I thought that the sand that was tracked aboard would blend in with the brown tone better than a gray. Getting a quote for installation of $6000 for the front and back deck nudged me in the direction of installing the exterior carpeting myself. After a solid week worth of work, I understand why they charge so much for installation. Never the less, it came out well and I added features like the tan plastic stair caps to improve wear and longevity of the carpet (seems that the first place to wear out on carpet is always the nose of the stair treads). Safety Equipment. Every houseboat has the basic, required safety items; fire extinguishers, Personal Flotation Devices (PFDs), throw-able flotation, smoke and carbon monoxide alarms, etc. Of course, Serenity has a full complement of all those items, but, as someone that has gone to sea and had safety drilled into me, I went above and beyond when it came to safety equipment. I was always fond of the USCG motto of Semper Paratus, meaning always ready; it was much better than the NOAA Corps motto, which as near as I could tell was Semper Confusa (in basic training I was told that NOAA was an acronym for No Organization At All and my career seemed to reinforce that). I hope never to be caught wanting when it comes to vital equipment that might save a life; just like the boy scouts, always be prepared. The number one fear of most mariners is fire. Fire aboard a vessel is truly terrifying, especially a ship sailing in the frigid waters of Alaska; there is no fire department to call, you and your fellow crewmates are the only ones that can battle the blaze, and if you fail the only escape is the unforgiving ocean. I’ve gone through basic and advanced firefighting training twice; even with turnout gear and an SCBA (Self-Contained breathing Apparatus), getting near a raging fire was no fun. So, while I equipped the boat with 5 fire extinguishers, I was looking for better alternatives to battle a blaze. The engine compartment was already protected by a fixed HALON system, which should knock down a fire in that space in short order. It is a HALON 1301 Flooding System that is automatically actuated when temperatures in the Engine Compartment reach 175-deg F. HALON is a firefighting agent that attacks the fire by inhibiting the chemical reaction itself. It is very safe for human exposure and it is extremely effective at quickly knocking down a fire while leaving no residue. Unfortunately, it is a CFC and was linked to ozone layer depletion; as a result, production was ceased in 1994, but there are sufficient reserves to last well into the future for applications where HALON is necessary. I'm very happy to have it protecting Serenity's engine compartment. At the suggestion of my firefighter brother, I installed an automatic fire suppression system over the range called the “StoveTop FireStop,” which is a fixed Sodium Bicarbonate Dumping System. This system is automatically actuated when flames reach the device and ignite a fuse. The fuse triggers canisters of Sodium Bicarbonate, which are dumped onto the range to extinguish the fire by smothering; when sodium bicarbonate is heated it releases carbon dioxide gas, which deprives the fire of oxygen. My brother also pointed me in the direction of a new sort of extinguisher, the Elide Fire Ball. The Serenity is now equipped with 2 Elide Fire Balls, which act as fixed automatic fire suppression systems in the main salon above the electrical panel and in the aft stateroom. These Fire Balls can also be taken down and thrown into a space to combat a fire without having to make entry or attack the fire directly. They are a hollow polystyrene ball containing monoammonium phosphate dry chemical surrounding a small explosive charge. Flames will ignite a fuse, which will set off the explosive charge and distribute the firefighting agent evenly throughout the space. Medical emergencies, like fire, pose a unique hazard in a location as remote as Lake Powell. Minor and major medical problems can arise at any time and having someone on board with at least basic first aid and CPR knowledge could be the difference between life and death. I went through over a month of training (most of which I have forgotten; I don’t think anyone wants me giving them stitches or administering an IV) to receive my MPIC (Medical Person In Charge) certification and I wanted to be sure that I had all the required emergency medical equipment available if I would ever need it. The Serenity is equipped with a very extensive Medical Kit that will provide equipment for even advanced responders; from a Cervical Collar to stethoscope to SAM splints to Aspirin. I had to restrain myself from buying a back board and AED, but at some point I had to admit that the expenditure exceeded the likelihood of ever using the equipment. Either way, someone that is trained in emergency medicine should find everything they need for basic EMT level care in the utility closet. All the emergency equipment in the world isn’t worth a tinker’s dam if you don’t know how to use it and haven’t thought about how to react in an emergency. On board ships we had binders of Standard Operating Procedures and Emergency Procedures that we had to learn inside and out to get qualified as bridge watch standers. Similarly, I have taken great care in creating SOPs and Emergency Procedures for the Serenity. They detail the equipment aboard and how to use it with clear and concise explanations. This sort of information is invaluable and, likely to the consternation of some of the new owners, it is required reading prior to being authorized use of the boat. As part of our rules, the owner also has to conduct a safety briefing prior to departing the slip, to make sure that everyone aboard knows the key safety elements aboard the boat. Safety is everyone’s responsibility. Navigation Equipment. I’m a self-admitted navigation nerd, having spent countless hours on the bridge of a ship navigating through the inside passage to and back from Alaska, and I had to reign myself in so that I didn’t overdo the navigation equipment on Serenity. Realistically, there is very little navigation wise that you need on Lake Powell other than local knowledge, but there are a few things that can definitely make your life easier. I of course purchased a suite of charts for the Serenity, including the Fish-n-Map charts of the north and south lake, the Stan Jones map that I framed on the wall for quick reference, and Navionics Western Lake electronic chart package, which includes a very detailed electronic chart of Lake Powell. The electronic charts display well on the new Lowrance Elite 7 chart plotter and echosounder (that’s the hydrographer’s way of saying depth finder), which also gives you a wealth of information about water depth and temperature. I mounted the chart plotter at the upper helm, since that is where I would be driving once in open water, where the chart plotter would be most useful. While I would never want to navigate the lake at night (it’s specifically prohibited by our insurance), this would give me far more confidence in doing so. Navigating in open water is relatively easy, but maneuvering in tight quarters can be a nerve rattling experience. As such, I focused on adding anything that could make the process a little easier. I had to replace the rudder angle indicators, which are extremely helpful in close quarters. It’s a nightmare trying to maneuver that houseboat in tight spaces when you have to guess at where your engines are pointed. After pulling into the slip for the first time, I realized that the view behind the houseboat from the lower helm was limited, to say the least. Having someone on the back deck as a lookout works, but I thought it would be much easier if you could see for yourself. I installed a rear view camera to give the driver a clear view of what is behind the boat. We’ll also be installing rear view mirrors on both sides soon to increase visibility further. Luxuries. Now, if I had my way I’d have a much simpler houseboat, maybe an aluminum pontoon boat about 50-ft or less in length with a swamp cooler and camper appliances; something that would be inexpensive to operate and be a little bare bones. When I think about going to Lake Powell I don’t think about creature comforts, but I’m married now and apparently if I want my wife to come with me to the lake, I need a few luxuries. I also figured that some memorable features would make shares easier to sell. I went higher end on most things, like soft close doors and drawers on the cabinets and stainless steel appliances, but also added a few cool extras.

As I’ve said, the work on a boat is never finished, but this post pretty much wraps up the ongoing series on the refit of the Serenity. I’m sure I will have many projects on the Serenity to write about in the future (winterizing the boat, the installation of the water slide, replacing the canvas, etc.), so stay tuned.

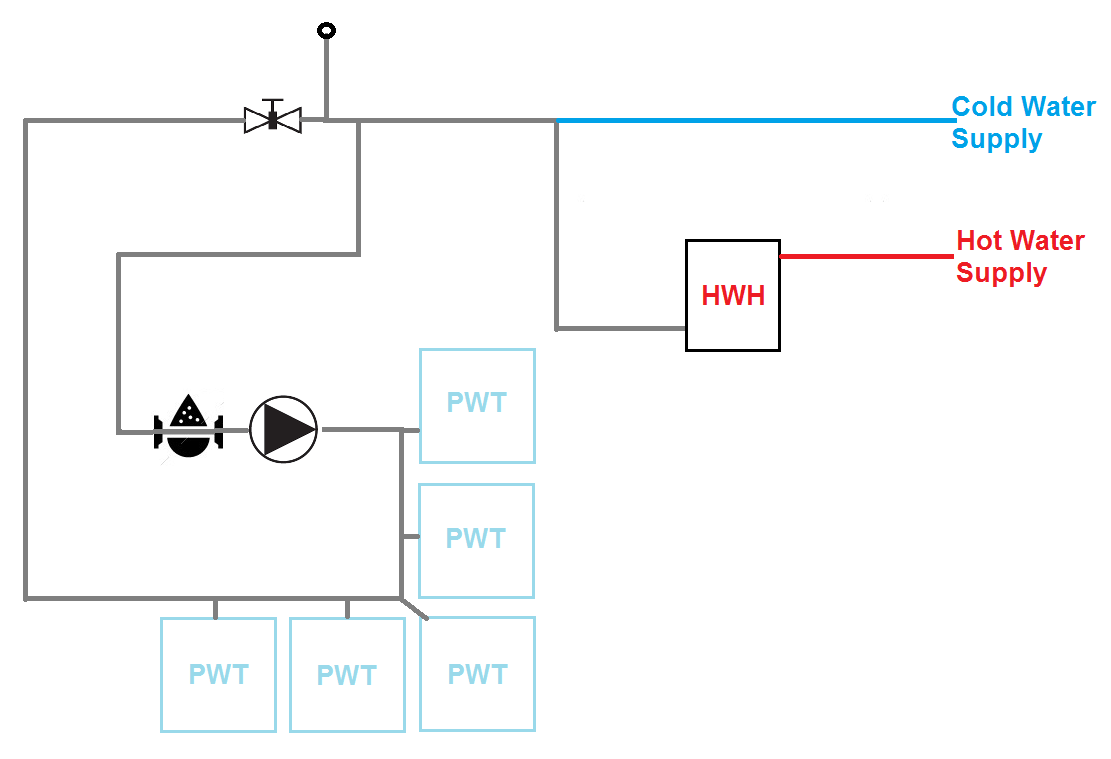

Until next time, here’s wishing you fair winds and following seas. When I was sailing on the NOAA Ship Rainier, we had no shortage of open houses and tours for everyone from Congressional staffers to local kindergarten classes. Giving tours of the ship, I got sick of drawing the analogy that the ship was “like a small floating city and was completely self-sufficient; producing its own power and fresh water, and treating its own sewage.” Never the less, it’s true and is equally true, though on a smaller scale, on a houseboat like Serenity. I’ve already address the electrical systems, so, as you may have guessed, this post is going to detail the plumbing systems. While the ship had water makers that turned sea water into fresh through evaporation and had a full MSD (Marine Sanitation Device) system that treated our waste water for discharge into the ocean, houseboats usually have far simpler systems. Generally you will find tanks on either end; potable water tanks to carry your fresh water supply and black-/gray-water holding tanks to carry waste until it can be pumped out. There are some houseboats that have water makers (usually reverse osmosis), but a majority are like Serenity and just have potable water tanks for your drinking water supply. The Serenity is somewhat unique in her fresh water configuration; supposedly the original owner liked to take long, fresh water showers and ordered it from Sumerset with five 80-gallon fresh water tanks, for a total of 400-gallons of potable water. The tanks are interconnected to act as one tank; connected via the fill lines and vent lines at the top and the supply lines to the pump at the bottom. With so much potable water, they made the unusual decision to not have a lake water system. Every other houseboat that I have experience with has a separate system run to the sinks and shower that is supplied by drawing water directly from the lake. That way you can use the lake water for all your non-potable applications and conserve the potable water. Aside from the fact that you are pumping your water from these tanks, the houseboat’s water supply lines are virtually identical to those you would find in a home…or more precisely, a mobile home. All the piping on the houseboat was gray polybutylene (PB), which was widely used in stick built homes, but was even more common in the mobile home industry. For anyone that knows plumbing, they’re probably cringing right now. PB was the precursor to the PEX lines that are commonly seen today, but was plagued with installation problems, connector failures, material degradation, and other issues leading to catastrophic failure. It was manufactured from the 1970s through the mid-90s, but was phased out amid lawsuits regarding homes damaged by water leaks and the rewriting of plumbing codes to eliminate its use. There are any number of problems, particularly with early installations. Issues mainly had to do with the fittings (the acetyl plastic and aluminum crimp fittings were the most common source of failure), but also due to micro-fractures in the pipes that resulted from excessive UV exposure or chemicals in the water. Many would have gone the route of completely re-piping, but unlike a house, I think that replacing the pipes as needed is more reasonable. Luckily, the fittings on Serenity were all compression fittings, which did not display the same issues found in the crimp fittings and have proven reliable. The PB piping itself has also held up very well and shows no sign of deterioration (inside or outside the pipe). In a house, if a PB pipe failed, you would likely be looking at tens of thousands of dollars of damage; you might not be home when the leak occurred and thousands of gallons of water could be unleashed into your home, damaging drywall, dropping ceilings, and doing other major damage. Unlike a house, the houseboat’s water system should only be pressurized when someone is aboard, so a catastrophic failure should be noticed, and the water would drain relatively harmlessly into the bilge, where it could be pumped out without causing nearly as much damage as in a house. If the pipes were in good condition, I left them as they were. However, anywhere that I needed to do plumbing work, I swapped them out for PEX lines, using the specialized crimp adapter to convert from PB to PEX. As future work is done, I expect all the PB pipes will be swapped out to PEX eventually. We will just need to monitor the system to make sure it doesn’t have any issues. The system itself is fairly simple. As illustrated below, there is a fill point on the starboard side of the houseboat, which will pressurize the potable water system or will fill the five potable water tanks if you open the valve inside the hatch just aft of the helm station. Once the tanks are filled, you can pressurize the potable water system with the pump, which needed replaced with all the other electronic components. In pervious boats and my parent’s campers I was accustomed to the buzzing rattle of the pump, but to my pleasant surprise, the pump I put on Serenity (a SHURflo 12-V, 3-GPM, 55-psi self-priming diaphragm pump) is virtually silent. From the salon, directly over where the pump is mounted, you hear nothing when it is running and you get a consistent, steady stream of water from any of the taps. When utilizing the on board water supply, the water is pumped through a UV filtration system before it ends up at the faucet. The UV filtration system, “The Water Fixer,” was installed prior to my taking ownership of the boat, but I did get the fun of completely rebuilding it. I purchased new filter housings, new ballast and electronics, new bulb, new quartz tube, and rebuilt the stainless steel housing for the UV tube. There is a two stage particulate filtration (standard mesh filter and charcoal filter) before the water passes through the UV chamber, where any living microorganisms that managed to make it through the filters should meet their fate. The water aboard Serenity should taste as fresh as if it had come from a mountain spring. From the filter, the water goes to the individual fixtures as the cold water supply and also runs to the hot-water heater. The water heater, of course, needed to be replaced; I went with a 10-gallon Reliance 120-V hot-water heater that was a pretty straight forward swap out. Then the hot water is run to the individual fixtures, just like in a house. As shown in the above diagram. As far as waste water, Serenity is old enough that she was built with no gray water tanks and instead discharges gray water from the sinks and shower directly overboard. Other than plumbing in the new sink drains, the gray-water discharge didn’t need any work. The drain from the shower and sinks just run via standard PVC drain pipes to a stand pipe towards the stern and is discharged overboard. Serenity does have three 80-galon holding tanks for black-water from the two marine heads. It is a mystery to me, with all the room in this hull to position the holding tanks, why they didn’t do drop heads. Drop heads are far cheaper and simpler with less likelihood of failure, but instead they have two marine heads. The heads are Raritan Atlantes 12-V macerating heads, which I got to rebuild (no end to the fun of fixing up this houseboat). I contacted Raritan Engineering and got all the replacement parts to upgrade them to the current models (A8), which basically replaced all the internal components on the porcelain bowls. Each head has an electrical switch attached to the flush handle; that switch actuates either the macerator pump that removes water and other…waste…from the bowl and pumps it to the holding tanks, or the supply pump that feeds water into the bowl. While I did say earlier that the Serenity did not have a lake water system, I suppose that statement isn’t strictly true as both heads have dedicate supply pumps that draw lake water from seacocks. These are the only points, aside from engine cooling water, where Serenity pulls lake water aboard. I’m glad that I didn’t have to deal with multiple lake water systems, mainly due to my concern with the Quagga mussels that have recently been moving into the north end of Lake Powell. However, this still leaves me to worry about the potential damage they might do the black-water system and I have spent far too much time researching potential solutions. I haven’t found anything definitive on whether these mussels will cause problems in the black-water system, but it stands to reason that since they are a concern in waste water treatment plants that you might see similar issues in your houseboat’s black-water system. I considered several different options for preventing this theoretical damage and have found that there is a dearth of information on actual implications of these invasive mussels on boat systems and on appropriate and effective countermeasures. Chlorine and other chemical sterilization is proven to kill the mussel veligers. However, like most houseboats, Serenity is using an enzyme based toilet treatment and chlorine would kill off those desirable enzymes. Additionally, adding chemicals to the toilet to kill off the veligers wouldn’t really protect the pump or supply lines. If chemically killing the critters wasn’t an option, then I thought the next logical method would be to irradiate them. Serenity already has the UV filtration set up on the potable water, and I didn’t think it would be too difficult to add a UV sterilization chamber onto each of the supply lines, which would have no impact on flow rate. UV Sterilizers use short wavelength UV light to kill microorganisms on a genetic level; damaging their DNA so that they cannot perform basic, vital cellular functions. I just wasn’t sure that this would be completely effective on the mussel veligers. I only found one study on the efficacy of UV light at killing Quagga mussel veligers (note the link to the study now just redirects to the home page of the Aquatic Invasive Species Network, it appears they have taken down the study). This report looked at the effectiveness of single and multiple treatments though a UV sterilizer at killing Quagga mussel veligers. I didn’t think the conclusions were well supported by the data (they advocated multiple treatments with the UV sterilizer, even though after 96-hours 1-treatment has greater than 90% mortality rate, which was statistically the same as the multiple treatment runs) and I would have liked to have seen more definitive testing (they only looked at the mobility of the veligers in the sample up to 96-hours after treatment to determine mortality; I would have liked to have placed the samples into an ideal growth environment to see if any of the UV treated veliger samples would produce mussels) and a larger sample size (if I recall correctly, they only ran one sample for each treatment level). I briefly toyed with the idea of getting some water with veligers from Lake Powell and conducting my own experiments, but decided that 1) that would be a lot of work and 2) I’m pretty sure that knowingly transporting an invasive species across stateliness is probably against the law. I didn’t have my definitive answer, but I thought that it looked good and was about to start calling UV sterilizer manufacturers. Before I got to that, I posed the question on the Wayne’s Words Message board, figuring that I couldn’t have been the first person to deal with this issue. No one had considered this for combating potential mussel infestation, but UV sterilizers and filtration systems weren’t a foreign concept (mostly on potable water systems). One member had an issue with sediment getting picked up into his black-water system and had success with a standard canister filter system on the lake pick-ups. I had dismissed a traditional filter because I was worried about providing sufficient flow rate to the heads, which require at least 3-GPM, but he said he was using 5-micron filters in his system and had no such issues. In fact, he only changed the filter once a year. It may not be as high tech as irradiating the little buggers with UV light, but it should be completely effective (a 5-micron filter isn’t going to let any of the 70-micron or larger veligers through) and it was much cheaper. I decided to go ahead with installing high flow rate filtration systems. I purchase two 10-in filter canisters with 5-micron filters (rated at 5-GPM), which should have no issues removing the veligers. I’m hopeful that we will see similar results and not need to change the filters until the beginning of next year. Thus far, it seems to be working great with plenty of flow rate to both heads. It gives me one less thing to worry about; now I just wish there were a way to protect the engine cooling systems.

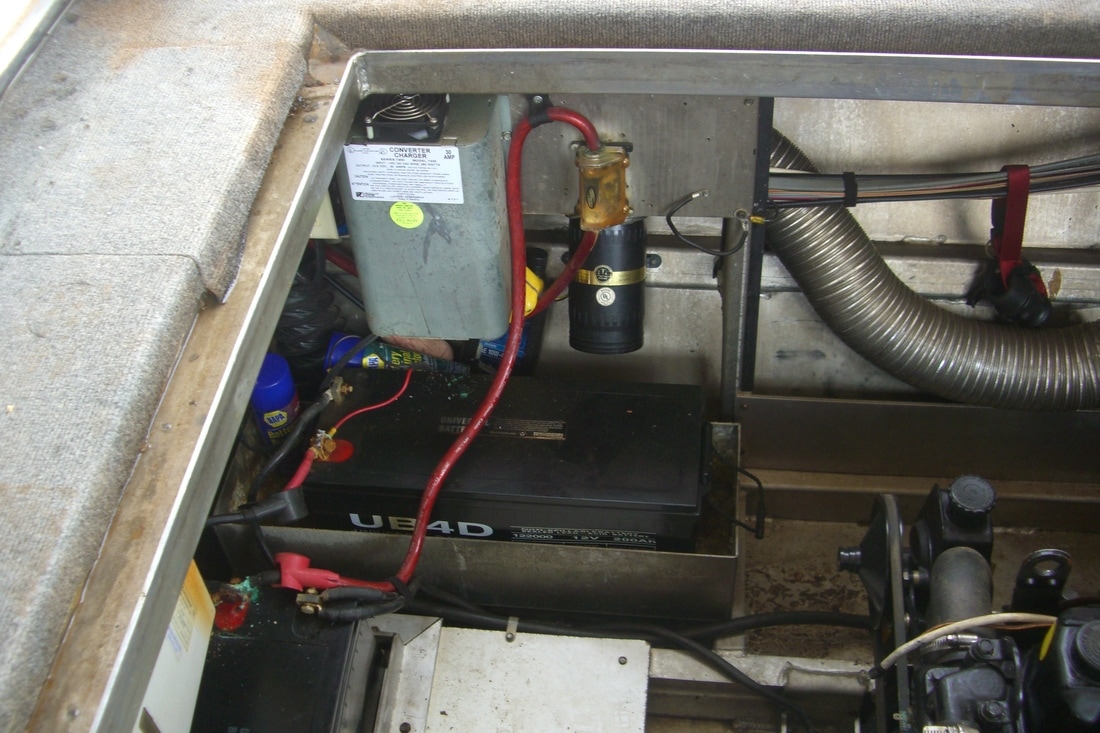

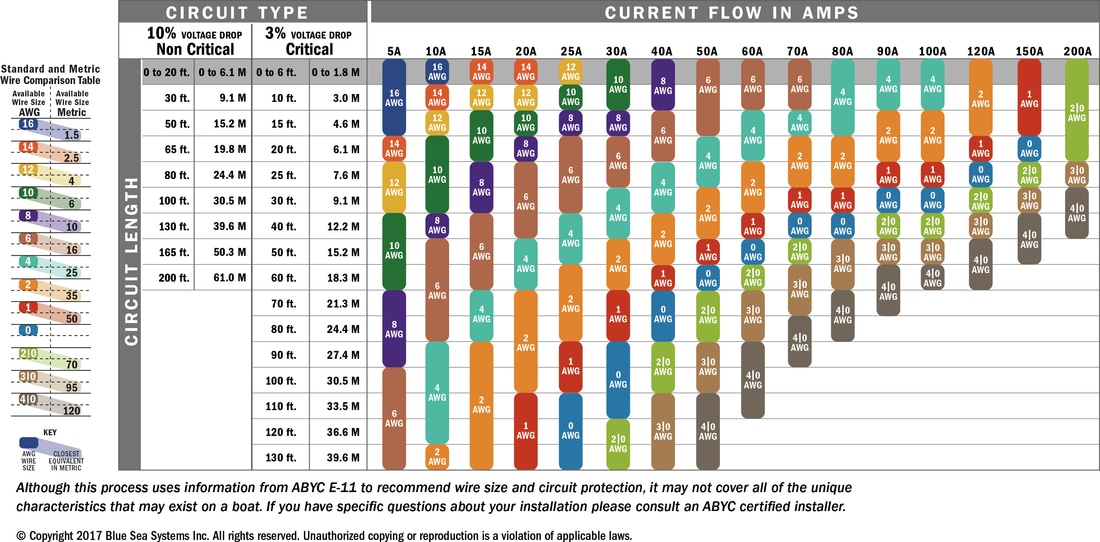

Until next time, here’s wishing you fair winds and following seas. One note of caution before I begin, in case you don’t remember the song from Louie the Lighting Bug, electricity is dangerous. While the 12-V DC system most likely won’t electrocute you (12-V isn’t high enough to overcome the relatively high contact resistance of the human body…I feel a tangent coming on and I haven’t even started the post yet) it can pose a variety of other dangers (high current can arc and cause fires or burns, and under the right circumstances lead acid batteries can explode). The 120-V/240-V AC system is a very real threat of electrocution (potentially fatal) and also has the risk of being the source of a fire. So, if you’re not comfortable working on your electrical systems, don’t; but you can still enjoy reading about them. I don’t know how I was so deluded that I let my dad convince me that the electronics on Serenity would be fine, but somehow I had this vision of just getting new batteries and having everything fire right up and work like a charm. I mean, nothing was powered when it went under water, it was only under for a couple days, and then it dried out in one of the most arid places in the world; sticking your cell phone in a bag of rice works, and what is the Great Basin Desert, if not a giant bag of rice. Well my giant houseboat shaped cell phone did not come back to life after drying out. As a rule, every piece of electronic equipment that was underwater needed to be replaced. Now, I could go on and list every component that was replaced, but that doesn’t make for a very exciting blog…unless you like lists. Suffice to say that we did end up replacing everything; from the outlets and switches on the 120-V system to the 12-V gauges and switches on the lower helm. There were a couple notable exceptions. The chest freezer on the front deck kicked on and froze my ice packs in a hurry; I kept it and assumed that when it did fail it would only be a couple hundred dollars to replace. The bilge blower worked, but had a new feature in a horrible squalling noise that let you know when it was on; you’d never forget to turn it off, but I eventually decided to replace it with a slightly quieter model. That’s it, literally every other electronic component was replaced with new. Instead of just listing the trials and tribulations of installing new electronics, I was thinking I would discuss the electrical systems aboard the houseboat in a more general way. Many people approach electrical work with trepidation and view the electrical systems on their houseboats as almost mystical in nature. I’m not going to advocate that a novice take on rewiring their home (see warning above), but I would say that a basic working knowledge of how your electrical systems work and confidence enough to troubleshoot minor problems might be a good place to start; ideally your electrical problem solving will extend beyond cycling the power (that’s a more technical way of saying "turning it off and on again"), though in some cases that does the trick. I had a lot of experience working with “system integration” on NOAA’s survey launches (getting the half million dollar sonar to talk with the quarter million dollar DGPS/Inertial navigation unit). I was up to my eyeballs in wiring diagrams, baud rates, NMEA strings, power requirements, and the like; most of which I have completely forgotten, but the experience was invaluable in tackling this project on the houseboat and keeping things in perspective and organized. I’ll break the Serenity’s electrical system down into 3 sub-systems; the DC house system, the AC house system, and the engine system. Each of those sub-systems could then be broken down further into more sub-systems, and so on until you got to individual components. Looking at it this way makes what could be a complex and overwhelming project (i.e. rebuilding the entire electrical system) seem far more manageable. You just have to tackle one sub-system at a time until you get the whole working. The three main sub-systems were easily separated and were, for the most part, standalone systems and would function completely independently from one another. The first one that I wanted to get working was the 12-V engine systems, which are the critical systems to run the boat that can be seen as analogous to the systems you have in your car. These are common to a 14-ft runabout or a 65-ft houseboat. The navigation lights, the instrument clusters, the bilge blower, the engine’s electrical controls, etc. Unfortunately, I wasn’t able to address most of these components until the new engines were installed and the wiring harnesses were in place, which seemed to keep getting put off. So, I ended up finishing up the other two systems first. The DC house system, often referred to as the 12-V system, is relatively simple, especially if you break it down to its basic components. I think most of us probably learned about electricity in elementary school by connecting the positive and negative sides of a battery to the appropriate terminals on a light bulb, maybe even throwing in a switch, which demonstrates a basic DC electrical circuit. That is all that the 12-V system is on the boat, a DC circuit that just has a few more parts. You have a bank of 12-V batteries (in our case two sealed lead acid deep cycle 200-Ah batteries) that feed a distribution panel (i.e. the breaker panel) and then power any 12-V components. Primarily on the Serenity, these were the 12-V lights, but also include radios, water pumps, and a few other 12-V components. The two batteries are wired in parallel (i.e. negatives-to-negative and positive to positive) so that they supply 12-V, but output Amperage is doubled. The positive lead is then protected by a circuit breaker (in our case a 100-A breaker). I will note that this could be fused protection, but I prefer to use breakers whenever possible. If you trip a breaker, say by accidentally shorting the positive and negative connections on a 50-A breaker (not that I have ever done this), then it’s only a matter of resetting the breaker; if you blow a fuse, you will quickly discover that nowhere within 50-miles of Bullfrog has a 100-A replacement fuse and the only way to restore power is to bypass the fuse protection or improvise your own “fuse” (say a piece of 12-ga wire). From the 100-A breaker our supply line ran to three 50-A breakers in the engine compartment, which in turn fed the two marine heads (each head was on its own 50-A breaker) and the main DC breaker panel. Power is then run through appropriately sized breakers on the panel to feed those circuits. At each step away from the batteries, we move to a smaller breaker (e.g. 100-A to 50-A to 10-A or 20-A at the panel) and smaller wire size. You just need to be sure that your wire is appropriately sized for the amperage and the length of the run, which can quickly be determined by consulting the chart below (courtesy of Blue Sea Systems, which has a great article on selecting appropriate wire size here). Then you just need to make sure you have breaker (or fuse) protection for that run of wire. The supply line is connected, often through a switch, to your component (light, pump, radio, etc.) and the negative is connected back to the battery, often through a bus bar, to complete the circuit. The house DC system is pretty simple, but it was not without its gremlins. The biggest hurdle we had to overcome was an intermittent problem that I initially thought was a dead short on one of the circuits. We spent an entire day trying to isolate the problem, but intermittent problems are the toughest to diagnose. The system was working without an issue right up until we had our marine survey; during his inspection he couldn’t get any of the DC components to operate. We could energize the entire DC panel without issue, but when we would put a load on the system the voltage would intermittently drop to zero. The reason is obvious now, but I was ready to bribe a friend that was an electrician to come down and figure it out for me. As anyone who has struggled with trailer wiring probably knows, the first thing you check is always the ground, which is where I should have started in this case. One of the ground wires in the engine compartment was loose and, I'm guessing, the marine surveyor disturbed it when he was crawling around and it resulted in an intermittent connection problem. Tightening the cable solved the problem. With that done and the engines still not installed, I moved on to the AC system. I will often refer to this as the 110-V system, though that is not really accurate. On the houseboat, as in your home, we have a two phase AC system, with two legs of 120-V alternating current that are 180-degrees out of phase with each other. The power at your receptacles should be 120-V, but due to resistance in the system that voltage can often drop to 115- or even 110-V. Many appliances will be rated at 110-V, which only indicates that they can safely operate at these reduced voltages, but they are actually made to run on the 120-V circuit. So, at least in this blog post, I will be referring to them as 120-V and 240-V, but know that if you see references to 110/220 or 115/230 they are referring to the same AC power supply. I don’t want to get too mired in theory (maybe I do), but it’s important to understand that your AC power is being delivered on two 120-V legs and that you can feed 120-V circuits by drawing from one leg to neutral or you can feed 240-V circuits (ranges, microwaves, HVAC systems, etc.) by using both legs. Aside from the above, the AC system is wired much the same as the DC system, running from the main distribution system (i.e. breaker panel) to all the individual circuits, just like your home electrical system. On the panel of Serenity you have three banks of breakers; the two outer columns are 120-V breakers and the center column are all the 240-V breakers. The obvious difference between your average house and the houseboat is that the houseboat has three options for the power supply. The entire panel can be run by either connecting to shore power (e.g. the power grid) or the onboard 12.5-KW genset; or, a subset of specific systems can be run by the inverter. The inverter and its dedicated bank of six 6-V 370-Ah batteries, of course, needed to be replaced. The batteries are in a separate compartment at the bow of the boat and are wired in series to create a 12-V bank (i.e. two 6-V are wired in series to provide 12-V and then each set is wired together in parallel to triple the amperage rating). The inverter is set up to provide power to the refrigerator and the entertainment center, as well as a few other minor items on those circuits. It is also supplied through the power panel to act as a 150-A charger when there is shore or generator power to recharge the batteries. I have a control panel for the inverter mounted by the main electrical panel, but it operates automatically in most situations. If the breaker is on and there is power available, it will automatically go into a charging cycle and, when the batteries are fully charge, will then shift to a maintenance charge. When power is lost, it will automatically shift to inverting after a few minutes. The one thing that has been necessary to fiddle with on the control panel is adjusting the charge rate, especially if you want to operate another heavy load like the range, microwave, or HVAC systems. I found 70% seems to work pretty well, but haven’t tried operating another big load and the 150-A charger at the same time on generator yet; it might mean lowering that charge rate even more so as not to put too much load on the generator. Finally, we come to the engine electrical systems…but, just like me, I think you’re going to have to wait. As I said above, these systems are largely the same from a 14-ft runabout to a 65-ft houseboat and I think I would do them more justice by devoting a full blog post to them in my series on the refit of my Lone Star Malibu.

Until next time, here’s wishing you fair winds and following seas. They say it’s what’s on the inside that counts and, in the Serenity’s case, she was as ugly on the inside as she was outside. So we ripped out her guts and replaced them with new shiny guts. If nothing else, you will get a lesson in nautical terminology and will get an idea of what my first few weeks on a ship were like; “it’s not a door, it’s a hatchway FNG….there are no stairs on a ship, Butter Bars, they’re called ladder-ways…it’s a head, if you want to use the toilet, swim to shore.” Ah, good times. As you can see from the previous photos, the interior of Serenity needed some serious help. It was a time-warp back to the mid-90s with its pickled oak, brass fixtures, and white appliances. Oh yeah, and it was underwater for a few days and seemed a little worse for the wear. I really was shocked by how much water damage there was and how much was not salvageable. The finish on cabinets and walls was peeling, plywood paneling was delaminating and bowing, cabinets were literally coming apart at the seams, the doors were falling apart, and everything was coated in an oily, sandy grime. It wasn’t a place that you wanted to spend a lot of time. And did I mention the style was straight out of the mid-90s. By the time we were done about the only thing that remained original were the overheads (that’s the ceiling for you lubberly types, on a ship a ceiling is something you stand on and the thing over your head is, well, an overhead). First came demolition. We hauled off the water damaged furniture, broke out probably 500-pounds of granite tile countertops, demoed the cabinets, pulled up carpeting, took out the doors, removed damaged paneling, and got rid of the appliances. Then we made our first tactical error; I had been thinking of keeping the tile in the galley (that’s kitchen), but my dad noted that they had installed it around the cabinets and that our new cabinets wouldn’t fit the holes. He also pointed out that the tile didn’t really fit the planned new décor, which I agreed with and agreed to tearing it out. About three days later we realized that someone was really good at laying tile; they had set down 1/8-in cement backer board with mastic, screwing it down every 6-in or so, and then put a generous amount of thinset down to lay the ceramic tile. We had broken up all the tile with roto-hammers, but the backer board did not want to let go and we finally came to the realization that the only way we were going to get the floor out was to tear out and replace the plywood subfloor. It took another couple days to clean up the edges enough to use our circular saw to cut out that section and pry it up. We then replaced the flooring with exterior grade plywood, which was rather straight forward…except for actually selecting the plywood for use. It is an interior area and for the most part is fastened to wood structure, but there are several aluminum deck beams that the decking material would be in contact with; why is this a problem you ask? Believe it or not, the internet is on fire with debate about what wood products to use on aluminum boats, but I have yet to find any authoritative sources on the subject. Without wading into the discussion too far myself, I think what I can take away from my hours of research is: (1) I should find a new hobby. (2) You should avoid using pressure treated lumber in contact with aluminum, because of the potential for increased corrosion in the aluminum due to the chemicals in the pressure treated lumber (I could elaborate, but...). (3) For areas that will not see excessive amounts of moisture, you can safely substitute exterior grade plywood for marine grade plywood; the chief difference is that that marine grade plywood should have no voids in the interior laminate layers to prevent trapped moisture from causing rot and it may have more layers. Since this floor was interior, it was more than reasonable to just go with the exterior grade plywood. With the easy part over, it was now time to put this mess back together. We started out with repairing and replacing damaged paneling; luckily we only found slight surface mold on some of the panels, with some significant bowing and peeling of the veneer. There were happily no signs of mold behind the panels that we removed and we gave everything a nice wash-down with Lysol. Once the paneling and subfloors were done, we sanded everything down and were able to quickly move on to painting. The original paneling was a pickled oak that was popular in the early 90s, but seemed a little dated. I decided to go for a more classical yacht motif and paint the bulkheads (that’s walls) an antique white with plans for mahogany or teak (at least something that resembled one of those woods) trim throughout. The paint went on smoothly; the trim on the other hand turned into I can't count how many days of endless fiddling with angles and lengths and trimming them…I really hate finish carpentry. While I started out with delusions of saving the old cabinets, it didn’t take long on our first trip back down there to realize that they were completely water logged and well beyond saving. The finish was peeling, most of the doors were warped, and a lot of the frames were starting to come apart. I went with solid wood cabinets with boxes made out of plywood instead of particle board. They might be slightly more expensive in the initial purchase price, but they are far more durable and will hold up in a marine environment much better in the long run. I also opted for the soft close doors and drawers. We hung the cabinets and installed new laminate countertops; I used laminate countertops for two reasons, (1) the extra weight of a solid surface countertop would have kept me up at night, and (2) there wasn’t a fabricator that I could find that would go down to Bullfrog to install a solid surface countertop. Also, I should point out that I would normally wait to install cabinets until after the flooring was down, but in this case, with our time limited down in Bullfrog, I didn’t want it to hold up progress; we had contracted out the flooring and, as I discovered with everything I contracted out, things take a lot longer to get done down at Lake Powell. Long before I purchased this houseboat I had fallen in love with this vinyl flooring produced by Lonseal that mimics the look of teak and holly sole. I love the look of teak and holly and nothing is more nautical than a cabin sole covered from stem to stern in teak and holly. I was not as in love with the price, the installation, or the upkeep of traditional teak and holly flooring. Luckily, several years ago they started producing exterior synthetic teak flooring (PlasTeak, NuTeak, and a variety of others) and a little more recently there were companies that began producing the vinyl sheet flooring that reproduced the look of teak and holly with all the benefits of a commercial vinyl floor. The Lonseal isn’t cheap by any means (the 300-sqft I purchased was around $2500 and the adhesive added a couple hundred), but it is durable commercial grade vinyl. The vinyl surface is designed for high traffic commercial area, completely waterproof, slip resistant, and UV stable; in short it should outlast the boat. Without taking a long hard look at it, you also wouldn’t easily be able to pick it out from a real teak and holly flooring. I opted to lay this vinyl flooring in the main salon (living room), galley (kitchen), and passageway (hallway, though that one should be obvious); not only does it look great, it also won’t trap sand that will inevitably be tracked aboard and cleans up easily with a broom and mop. The heads (that’s restrooms) were tiled in a Stain-master “Luxury” vinyl tile, which went down over a latex primer on the plywood deck. I did contemplate installing real tile, but there is something that is just un-seamanlike about putting extra weight on a boat; I figured if the vinyl tile doesn’t hold up I can always replace it in the future. The staterooms (that’s bedrooms) were finished off with Stain-master carpeting. I contracted out the Lonseal and carpet installation, but tackled the heads on my own. The old hollow core doors were in sorry shape and clearly needed to be replaced. I purchased traditional mahogany hollow core doors, stained and varnished them and then replaced the door hardware before hanging. The fixtures throughout went brass; I know many will think that dated, but brass was and is common on vessels for its superior performance in a marine environment…I can recall many an anchor watches as a new ensign spent polishing all the brass work on the bridge. Brass just fits with a traditional yacht décor. The exception would be the galley where I went with a stainless steel sink, stainless steel appliances, stainless steel faucet, and oil rubbed bronze (black) door and drawer pulls for the cabinets throughout. The last thing we had to do was to take a steam cleaner to the overhead to clean up some staining; then we just had to move in new furniture to complete my vision of a traditional yacht interior…if only doing it was as easy as writing about it. Until next time, here’s wishing you fair winds and following seas.